Concentrated Solar Power: Stirling Dish Systems

- Veehan Dash

- 2 days ago

- 2 min read

The next Concentrated Solar Power (CSP) system that I will cover is the Stirling Dish system, which contains a mirrored dish that reflects light, whose shape is similar to a large satellite dish. The numerous mirrors on the dish reflect and concentrate light onto the thermal receiver, and Stirling Engines, which is above the dish. The thermal receiver can either use a heat transfer fluid (HTF), which is connected to a Rankine cycle, or it can simply use a closed-rankine cycle, in which an intermittent working fluid, like water, condenses and evaporates. Both of which, transfer the heat to the generator. The heat created by the reflectors is typically around 750˚C.

The Stirling Engine uses the Stirling Generator, which is similar to a normal generator such that it takes the heat from the thermal receiver and converts it into electrical energy, however the Stirling Generator is slightly different, which is what makes Stirling Engines special. The Generator has a fixed amount of gas inside the generator itself, which will undergo temperature changes at the different sides of the engine. The hot source is the thermal receiver, while the cold source is simply cold air. The gas moves back and forth from the hot to the cold side of the engine. At the hot side, the gas heats and expands, while at the cold side, it cools and contracts. So, one side of the gas tube moves up due to the expansion of the gas, while the other side moves down because of its contraction. However, now the side that was higher than the other will cool down and move down, while the other will move back up. This cycle will repeat, which rotates the crankshaft of the engine, transferring the thermal energy to mechanical energy, which drives a generator and produces electrical energy. Additionally, Stirling engines have regenerators, which are heat exchangers that are inside the engine that saves some heat from one cycle for use in the next.

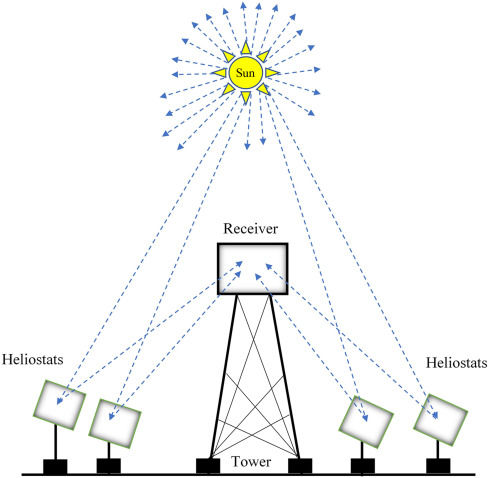

Figure 1: Schematic Diagram of Stirling Engine

Stirling Dish systems typically have one of the highest efficiencies because it creates such high temperatures, and it also has a longer durability. However, the main disadvantage that makes Stirling Dish systems seem unappealing to developers is that it requires high initial costs, which is due to the fact that the dish requires several curved mirrors, as well as the fact that the several heat engines require constant maintenance, which can be quite expensive.

Comments